Optoélectronique de Fuzhou Meiyang : des équipements haut de gamme établissent une nouvelle référence en matière de fabrication de précision de composants optiques

La précision d'usinage et la stabilité de la qualité des composants optiques de précision sont les piliers du développement de pointe de l'industrie optoélectronique. Fuzhou Meiyang Optoelectronics, entreprise engagée depuis longtemps dans le domaine des composants optiques et dont le développement technologique est le moteur principal, a fièrement introduit deux équipements de classe mondiale : le système de finition par faisceau d'ions IBF ÅFiSy IFS300A et le mesureur de contrainte de biréfringence Exicor 150AT. Grâce à leurs performances exceptionnelles et à leur grande adaptabilité, ces appareils offrent une solution complète pour la fabrication de composants optiques de moyenne et haute gamme, couvrant l'ensemble du processus, de l'usinage ultra-précis au contrôle qualité. Ils témoignent ainsi du savoir-faire et de la vision technologique de l'entreprise dans le domaine de la fabrication optique.

ÅFiSy IFS300A : une référence nationale pour le traitement ultra-précis des composants optiques

L'ÅFiSy IFS300A, équipement de polissage par faisceau d'ions haut de gamme le plus vendu en Chine, a permis de remplacer les importations et d'assurer un contrôle national indépendant, avec un volume de ventes cumulé dépassant les 40 unités. Il a bénéficié de la reconnaissance et des achats répétés d'entreprises de premier plan telles que Fujing Technology, Huawei et Changguang Satellite, s'imposant comme l'équipement de choix pour le traitement ultra-précis des composants optiques. Basé sur le principe de la pulvérisation ionique sous vide, cet équipement permet une mise en forme de surface par enlèvement de matière à l'échelle atomique, ses principaux atouts étant son avance technologique et sa fiabilité d'application.

En termes de configuration de base, l'équipement est doté d'une source d'ions radiofréquence IoT d'origine allemande, associée à un système breveté de coupelle Fraday et de sonde de mesure de coordonnées. Ce système permet une précision de serrage et de positionnement répétable supérieure à 5 µm, garantissant ainsi une précision optimale pour le traitement des composants optiques. Il adopte une structure à grille de graphite à trois couches et une conception de diaphragme personnalisable, permettant un ajustement flexible de la taille du faisceau afin de répondre aux besoins de traitement de composants optiques de différentes spécifications. Côté performances, la précision de traitement atteint PV ≤ 15 nm et rms ≤ 0,5 nm. Après optimisation du processus, la rugosité de surface peut atteindre Ra ≤ 0,3 nm et la stabilité de la fonction d'enlèvement de matière dépasse 95 %. L'erreur maximale d'efficacité maximale lors d'un traitement continu de 8 heures n'est que de 2,76 %, assurant ainsi la constance et la fiabilité de la production en série.

En termes d'adaptabilité, cet équipement prend en charge le traitement de divers matériaux optiques tels que le quartz, le saphir, le carbure de silicium et le CaF₂, et est parfaitement compatible avec les composants optiques aux structures complexes, notamment les surfaces planes, sphériques, asphériques, asphériques hors axe et de forme libre. Son procédé de traitement sans contact évite les effets de bord et les dommages sous-jacents. Doté d'un logiciel de contrôle et de calcul développé en interne, il est compatible avec les interfaces de données des principaux équipements de test, tels que les interféromètres Zygo. Grâce à plusieurs itérations de traitement, il permet d'optimiser significativement les défauts de forme de surface des composants optiques, améliorant ainsi considérablement leur transmittance lumineuse et la qualité de leurs images. Il constitue un atout majeur pour la R&D et la production de composants optiques essentiels, tels que les lentilles haut de gamme, les fenêtres optiques et les objectifs lithographiques.

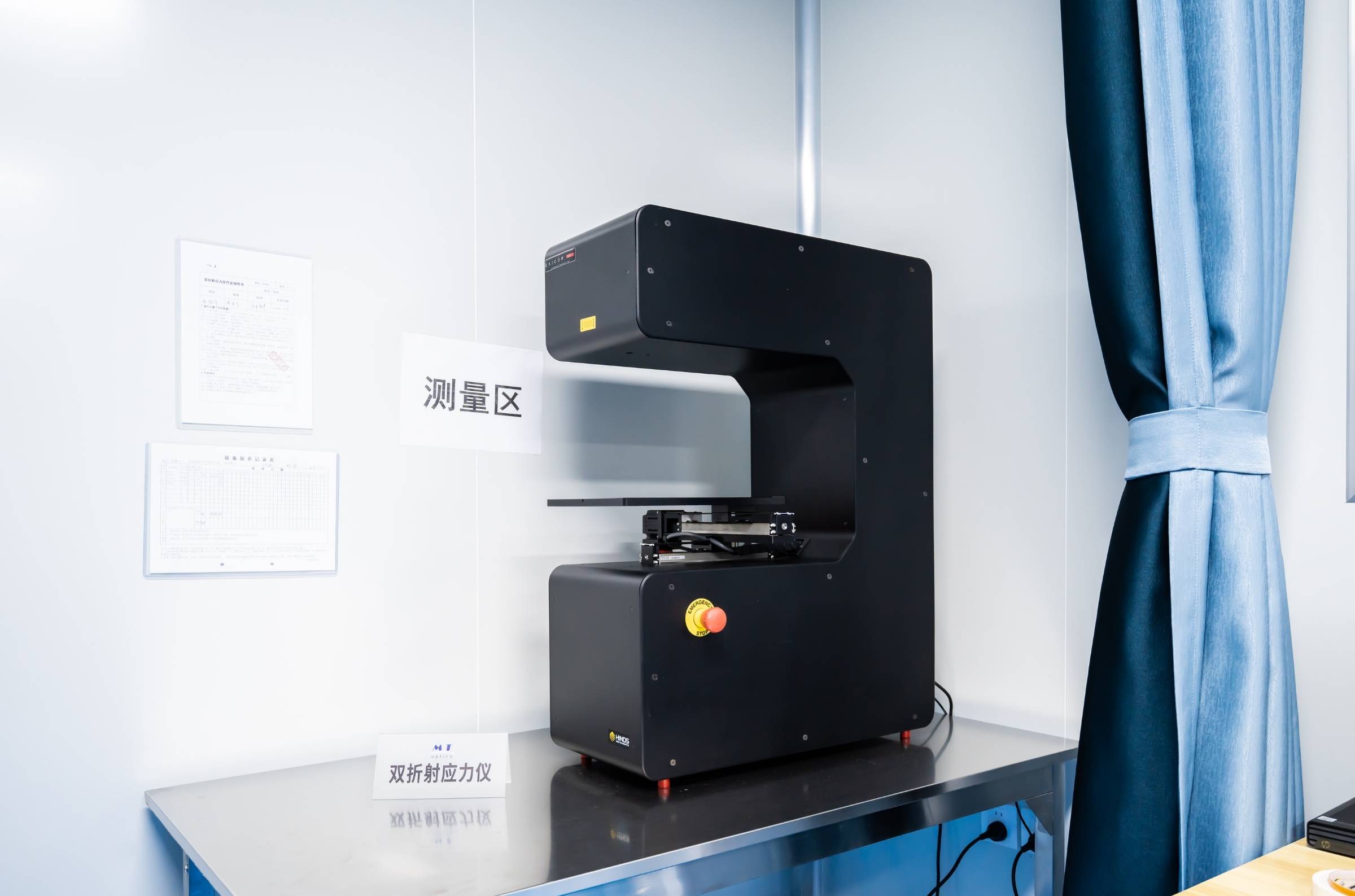

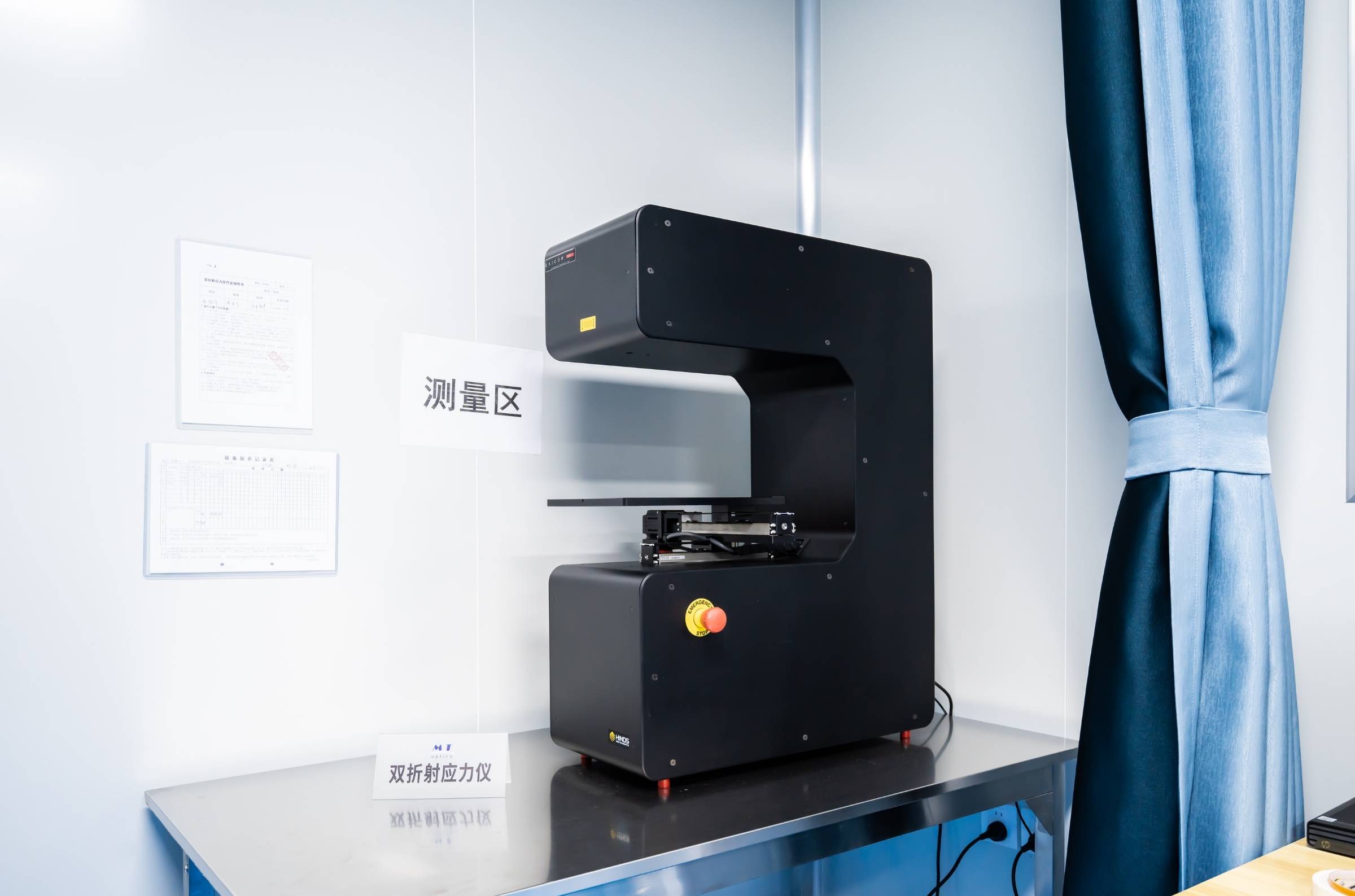

Exicor 150AT : Un outil de précision pour la détection des contraintes des composants optiques

Les contraintes résiduelles constituent un facteur clé affectant les performances optiques, la stabilité mécanique et la durée de vie des composants optiques. L'Exicor 150AT, grâce à sa capacité de détection de haute précision, est devenu un équipement essentiel pour le contrôle qualité des composants optiques. Basé sur le principe de la détection de la lumière polarisée orthogonalement, cet équipement intègre des technologies avancées d'imagerie optique et de traitement du signal pour mesurer avec précision la distribution de la biréfringence et les contraintes résiduelles des composants optiques.

En termes de performances, l'équipement offre une précision de mesure de la biréfringence de ±0,1 nm et une plage de mesure des contraintes de 0 à 500 MPa, permettant une identification précise des variations de micro-contraintes dans les substrats et les produits finis tels que le verre optique, les cristaux optiques et les matériaux optiques polymères. Doté d'une caméra CCD haute résolution de 1920 × 1080 pixels et d'un logiciel d'analyse professionnel, il visualise la distribution des contraintes et fournit des données exploitables pour l'optimisation des procédés. En pratique, l'équipement couvre l'ensemble du processus, du contrôle qualité à réception des matières premières à l'évaluation des performances des composants optiques finis, en passant par le suivi de la qualité en cours de production. Il permet le contrôle de composants optiques de différentes spécifications et formes et est équipé d'une platine porte-échantillon réglable pour s'adapter aux exigences de test de divers produits tels que les lentilles, les prismes et les fenêtres optiques, garantissant ainsi la conformité de chaque composant optique aux normes rigoureuses des applications haut de gamme.

L'utilisation de ces deux équipements de pointe a non seulement permis d'améliorer le système d'équipements de base de Fuzhou Meiyang Optoelectronics dans le domaine de la fabrication de composants optiques, mais a également permis une montée en gamme de ses capacités, passant d'un traitement ultra-précis à un contrôle de précision. À l'avenir, Fuzhou Meiyang Optoelectronics continuera de s'appuyer sur des équipements de pointe et une équipe technique professionnelle pour fournir à ses clients des solutions de fabrication de composants optiques personnalisées. Grâce à des produits et services précis et fiables, l'entreprise contribuera au développement de pointe de l'industrie optoélectronique et permettra à l'industrie chinoise de la fabrication optique de précision d'atteindre de nouveaux sommets.